The internal structure principle of the on-board charger. The on-board charger is a charger that is fixedly installed on the electric vehicle. It uses AC power as the input and the output is DC to directly charge the power battery to realize the safe and automatic charging of the power battery of the electric vehicle.

Pictured: On-board charger produced by Max Power

Regarding the structure and composition of the on-board charger, I believe that many people are still not very familiar with it. Today, I will tell you about the structure of the on-board charger.

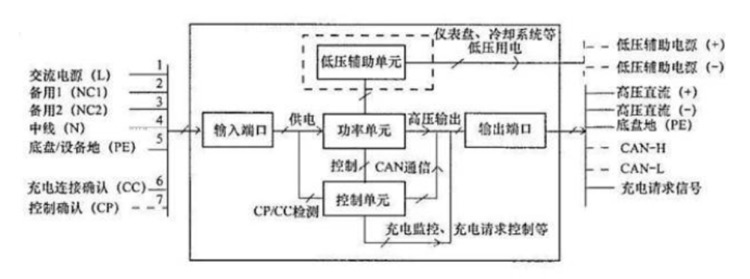

The on-board charger is composed of an input port, a control unit, a power unit, a low-voltage auxiliary unit and an output port.

The picture shows:the composition of the on-board charger

7 pin ports, three types of connections, including high-voltage power supply connection, high-voltage neutral line, vehicle chassis ground, low-voltage signal charging connection confirmation and control confirmation.

The standard input interface adopts power frequency single-phase input voltage of 220V, but if the power is required, two spare pin ports(pin ports NC1 and NC2)can also be enabled to realize 380V input.

The output current and voltage are sampled, and after processing, the real-time values are passed to the PID control loop. (PID:a closed-loop automatic control technology, which is the abbreviation of proportional, integral and differential controller)

The controller compares the gap between the measured value and the expected value, and then transmits the adjustment request to the PWM circuit(PWM pulse width modulation technology).

Use pulse width variation to control the length of on-off time of power devices in the high-voltage circuit, and finally realize the output current and voltage as close as possible to the values required by the main control system.

The low-voltage auxiliary unit is a standard low-voltage power supply with an output voltage of 12V or 24V. It is used to supply power to electrical appliances on electric vehicles during charging, such as battery management systems, thermal management systems, and automotive instrumentation.

It generally includes three parts:input rectification, inverter circuit and output rectification, which convert the input power frequency AC power into DC power suitable for the voltage of the power battery system.

These include two pin ports for the positive and negative poles of the low-voltage auxiliary power supply, two pin ports for the positive and negative poles of the high-voltage charging circuit, chassis ground, communication lines CANH and CANL, and charging request signal lines.

The two pin ports of the high-voltage charging circuit are connected to the battery pack, and the charging request signal line is used between the input port of the charger and the external power supply. After the charging connection is confirmed, the charging request signal is sent to the vehicle controller through the"charging request signal line". Simultaneously or after a short delay, the vehicle is powered by a low-voltage auxiliary power supply.

There are two parts inside the car charger, the charger control board and the power supply part(main circuit).

It is mainly used to control, monitor, measure, calculate, correct, protect, and communicate with the external network on the power supply part. It is the"central brain"of the on-board charger.

The main function is to convert 220V AC into 300V DC. The power supply is divided into two parts, PFC and LLC. In fact, we can regard PFC as AC/DC and LLC as DC/DC.

The above is the explanation of the structure of the on-board charger. The development of new energy vehicles is the key to solving environmental pollution and energy crisis, promoting the transformation and upgrading of my country's auto industry, and realizing the transformation of my country's auto industry from large to strong.

As one of the EV charger manufacturers, Max Power offers a wide range of high-quality EV charging solutions. Max Power China EV charger manufacturer is an excellent choice for anyone looking for an EV charger because of their focus on providing excellent customer service and a wide selection of merchandise. Max Power China EV charger manufacturer offers a wide range of charging options such as home, commercial and public EV charging stations. Our products are reliable, efficient and affordable. To meet the needs of different customers, we also provide a variety of charging options, including AC and DC charging.

Max Power China EV charger manufacturer has a professional team of engineers and technicians dedicated to providing customers with the best service. Our skilled team can advise you on the charging options that best suit your needs. We also provide installation services so you don't have to worry about getting your charger up and running.

Max Power China EV charger manufacturer also offers a variety of accessories including cables, adapters and connectors to ensure your EV charger is installed properly. They also have many safety features such as ground fault prevention to keep your car and charger safe. Max Power China EV charger manufacturer is committed to providing customers with high-quality goods and services. We are committed to providing our customers with safe and reliable charging options. We are also strongly committed to environmental responsibility and strive to reduce our impact on the environment.

Max Power China EV charger manufacturer is an excellent choice for anyone in the EV charger market. We provide a variety of products and service options, and serve our customers wholeheartedly. Max Power China EV charger manufacturer is an ideal choice for anyone looking for an EV charger because of its dedication to providing high-quality goods and services.